XDS RFID Roller Cabinet: Tool management

Home > IoT products in industrial traceability > XDS RFID Roller Cabinet: Tool management

NEXCAP® offering:

The X-Draw S RFID Roller Cabinet is the compact version of the X-Draw model. Smaller and lighter, it is ideal for mobile use on assembly lines or in maintenance workshops. Its usage characteristics and detection capabilities are the same as those of its big sister, X-Draw.

Challenges

Managing tools is a major challenge in Aeronautics, from their inventory to the risks associated with FOD (Foreign Object Damage) or FME (Foreign Material Exclusion). Each year, tools left behind or lost during assembly or maintenance activities account for 30% of civil incidents and constitute a significant breach of safety. Poorly organized tool management can lead to a significant loss of productivity; activities such as borrowing and returning tools or monitoring maintenance and calibration dates are time-consuming and costly.

*Subject to compliance with RFID tagging and layout processes

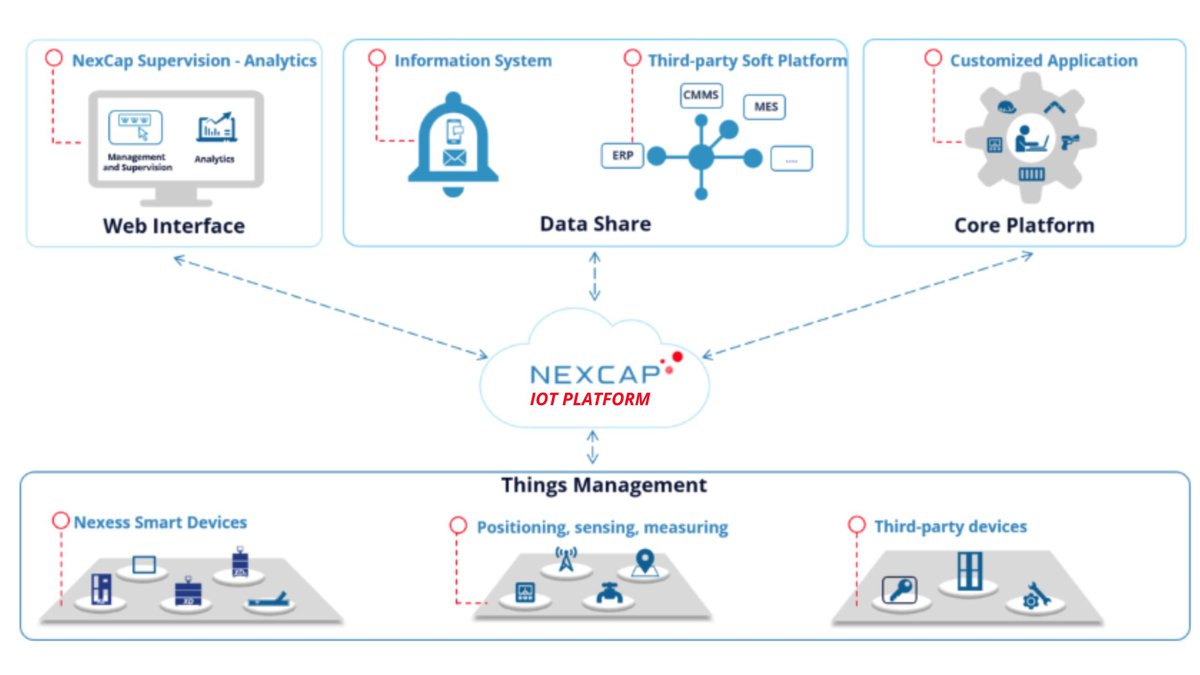

Things management, pour connecter facilement tous les objets :

Interface WEB